Are you prepared for the demands of your future customer?

Customer expectations are increasing, and the pace at which your company must evolve is as well. Delivering custom-configured products represents a sweet spot between standardization and uniqueness. However, managing a configuration-based manufacturing company comes with its challenges. Regardless of whether you excel in customer intimacy, product leadership, or operational excellence, what differentiates you today risks becoming the market standard in a short time.

Key challenges of configuration-based manufacturing

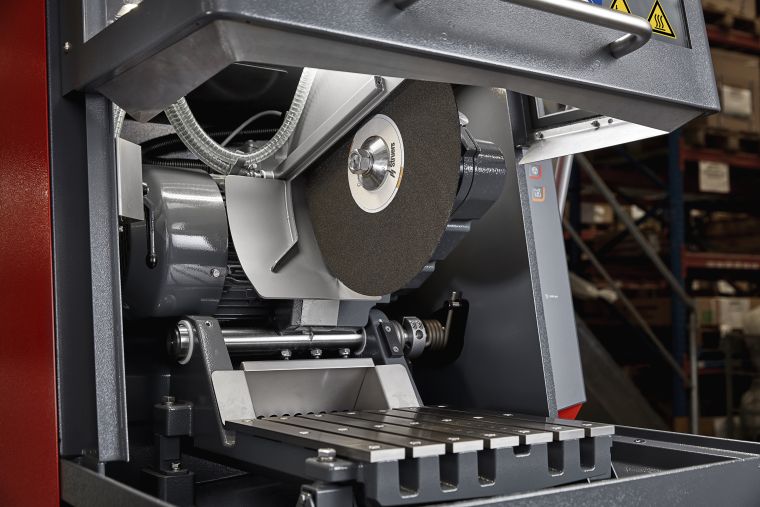

Maximizing operational efficiency

How do you ensure materials are available for production on time? How do you currently manage your resource planning to ensure that production aligns with capacity? Additionally, how do you handle rush orders?

These are some of the questions we pose to configuration-based companies. Why? Because having real-time insight into day-to-day operations is crucial. It's not just about having the right parts available; it's also about configuring them correctly to deliver the end product promptly.

To meet customer expectations, it's essential to reduce the time required to provide accurate quotes with the right configurations. Achieving this efficiently necessitates easy access to a wealth of information when creating quotes. Thus, a digital common thread is imperative for your organization.

Mastering challenges in configuration-based manufacturing

The more configurations your product have, the higher complexity. The complexity is challenging the overall efficiancy in all processes. With a integrated set-up, you become able to create the right balance.

Customer expectations is increasing. When your product is configurable, it can be time-consuming to calculate the right quote every time. Speed and precision can be hard to combine - but with the right tool, it doesn't have to be.

Making sure you always have the right raw materials available, while keeping your inventory level low and still enabling a high level of combinations, can be challenging. Integrated business applications can support you in keeping the balance - and notify you when a change of plans is needed.

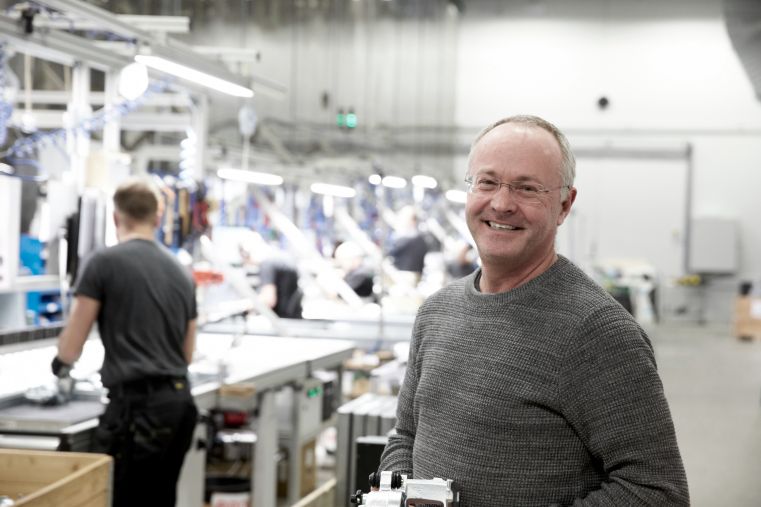

Many manufacturing companies experience a evolution in their business model. E.g. going from standardized products towards configuration-based activities. The journey can be challenging, and it's imperative, that your process and people get the right support.

Increasing customer expectations and rising prices makes is a challenging combination, when you want to keep your costs under control. With the right tools, you can become able to adapt your design, production processes and field services activities based on real-time insights. This helps you be in control - e.g. of your costs.

Your company's footprint is both affected by your direct and indirect actions - how do you e.g. take a raw material's CO2 footprint into account in your purchasing process? This is just one example of situations, where the right internal system should support your business processes.

Take charge of the digital common thread in your organization

No two companies are exactly alike. Your business, particularly your team, plays a crucial role in determining where you stand on your digital transformation journey. We're prepared to offer the support tailored to your unique needs. Whether you require strategic guidance for your digital transformation or assistance with specific business applications, we're here to assist you. Ready to kickstart your journey and scale new heights securely? You've got it. We've got your back.

Dive deeper in the solution you are looking for:

Are you leveraging AI in your manufacturing company?

Manufacturing processes often generate large volumes of data, which when using Artificial Intelligence (AI) to gain insights and trends in these data, can lead to significant optimizations. This is just one example of how you can leverage AI in your manufacturing company.