Complex products

The projects within NEDCON are becoming more complex over the years. With their previous 2D drawing system it therefore became more difficult to understand the designs properly: "We always drew with 2D and due to the complexity of the projects we noticed that it became increasingly difficult to properly visualize what we are working on ", explains Rens Jonker Business Project Manager at NEDCON. " Moreover, 2D requires more imagination, whereas with 3D you see the total aspect," says Norbert Martens Business Unit Manager at NEDCON.

Furthermore, NEDCON also wants to profile themselves as an interesting employer for their employees and future candidates. Given that students learn to work with 3D packages during their studies, it was natural for NEDCON to invest in a 3D solution.

The challenges for NEDCON

NEDCON wants to present themselves as an interesting and innovative employer for their current and future employees.

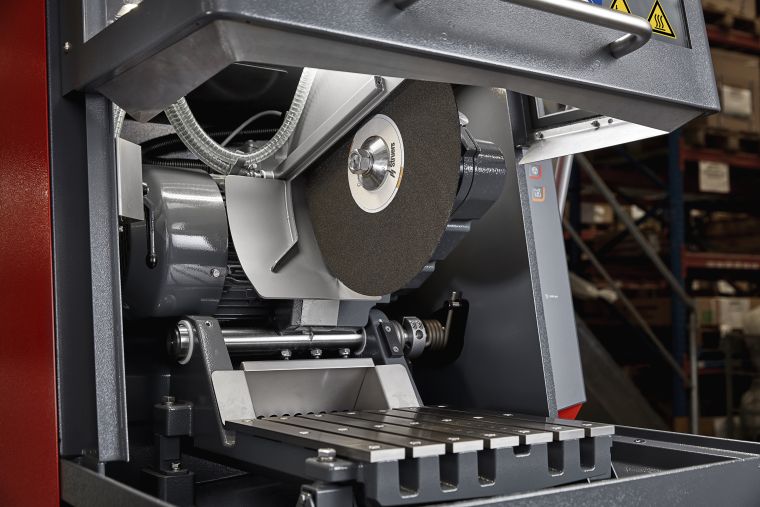

NEDCON's increasingly complex projects became increasingly difficult to design in a 2D drawing solution.

Rens Jonker

Business Project Manager at NEDCON

Impact of the change

Ultimately, NEDCON chose 9altitudes and the solutions PTC Creo Parametric (CAD) and PTC Windchill (PLM). By choosing a 3D drawing package, NEDCON explains that the working method within engineering changes completely. "You no longer work solely with drawings but with 3D models, moreover, that data is processed in a different way," explains Rens Jonker. "That impact is very big and we are now trying to implement it step by step within the company."

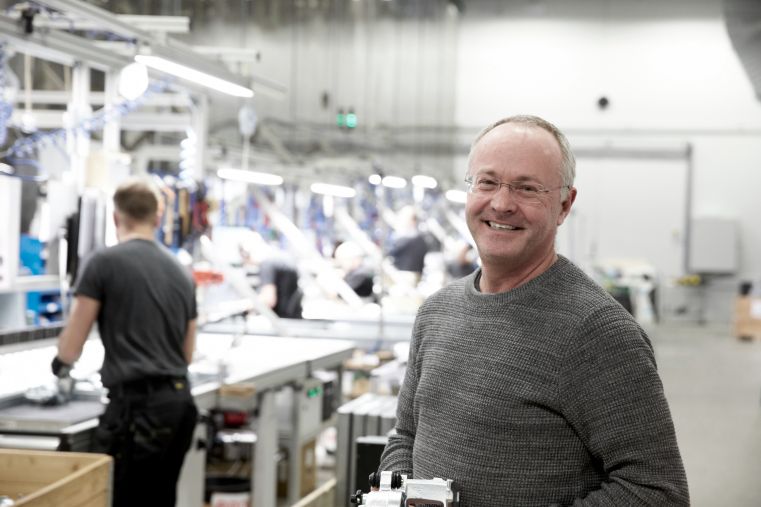

"Furthermore, we also expect a shift in the division of roles," explains Norbert Martens. "Where the engineering department used to only make designs in the 2D package, they are now integrating work preparation into their design as well with the modular system of Creo Parametric."

Expected results

Within the former 2D setup, errors in part counts happened. These NEDCON hopes to eliminate with the 3D setup.

Improved quality of products within NEDCON, ensuring higher customer satisfaction.

Within engineering, the modular design includes work preparations, making the engineering and production departments more closely aligned.

Norbert Martens

Business Unit Manager at NEDCON

Further steps

Implementation of the Creo Parametric and Windchill solutions has been completed. "However, you can achieve much more with the PLM solution Windchill. Towards the future we would like to explore this in order to take our production to an even higher level," says Rens Jonker.