What's excellent today, may not be good enough tomorrow

As customer expectations continue to rise, the pace at which your company must evolve is also accelerating. Your current competitive advantage, whether it's customer intimacy, product leadership, or operational excellence, runs the risk of becoming the industry norm in a short period of time.

Common challenges our project-based manufacturing customers are facing:

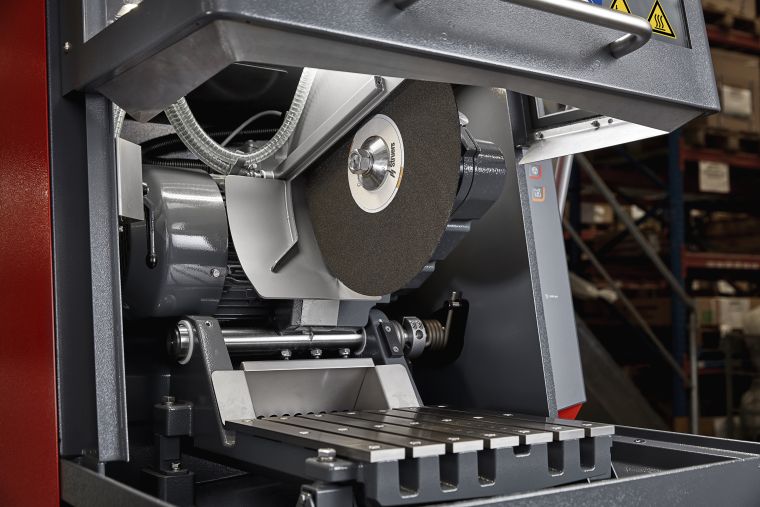

Project-based manufacturing

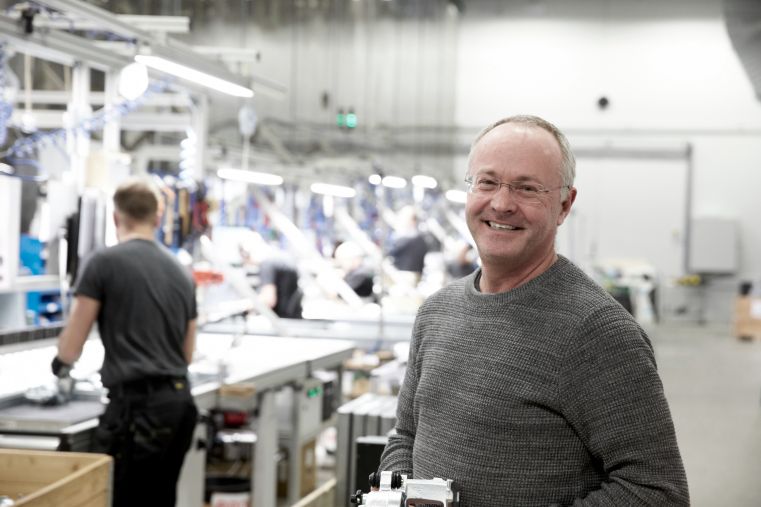

Successfully managing large, customer-specific projects requires the seamless integration of various elements. Meeting customer expectations, ensuring timely delivery of all components, providing regular progress updates, and adhering to budgetary constraints are essential for project success.

This efficient coordination necessitates collaboration among employees from diverse departments.

Challenges we have helped our project-based manufacturing customers overcome

One of the increasing market demands is the need for customizations. This creates more product configurations and increases your complexity. With a integrated set-up, you become able to handle this complexity efficiently.

The speed of which technology, products etc. evolve is only increasing. Therefore your time-to-market have a big impact on your customers experience. By connecting your design and manufacturing processes you can decrease your time-to-market.

Making sure you always have the right raw materials available, while keeping your inventory level low, can be challenging. Integrated business applications, you support you in keeping the balance - and notify you when a change of plans is needed.

Many manufacturing companies experience a evolution in their business model. It can be the evolvement of a pay-per-use model, a bigger focus on spare part production and offering service agreements.

Increasing customer expectations and rising prices makes is a challenging combination, when you want to keep your costs under control. With the right tools, you can become able to adapt your design, production processes and field services activities based on real-time insights. This helps you be in control - e.g. of your costs.

Your company's footprint is both affected by your direct and indirect actions - how do you e.g. take a raw material's CO2 footprint into account in your purchasing process? This is just one example of situations, where the right internal system should support your business processes.

Take charge of the digital common thread in your organization

No two companies are exactly alike. Your business, particularly your team, plays a crucial role in determining where you stand on your digital transformation journey. We're prepared to offer the support tailored to your unique needs. Whether you require strategic guidance for your digital transformation or assistance with specific business applications, we're here to assist you. Ready to kickstart your journey and scale new heights securely? You've got it. We've got your back.

Dive deeper in the solution you are looking for:

ERP pricing: what to expect for your business?

Our job is to simplify your journey to the summit, ensuring a smoother climb to new heights where you continuously feel safeguarded and in control. That's exactly why we've made it possible for you to obtain already a high-level budget estimation.

How? By completing this guiding questionnaire, we can estimate the project implementation investment and the monthly Microsoft license estimate, based on our experience in implementing many projects like the one you envision.

While Digital Transformation projects are typically complex and connected from many angles we tried to simplify this first budget indication for you based on our experience. However we would like to note that the questionnaire needs to take the full complexity of your business needs and the possibilities into account to give a good-fit budget indication, so please reserve between 5 and 10 minutes of your time to be able to answer the questions Your thorough responses will enable us to partner with you on your journey towards achieving remarkable digital transformation and success. Once completed, our system will instantly generate a customized estimate, sent directly to your email. No complicated steps—just a direct path to the solutions you need.

If the questionnaire feels too much, please reach out and we will contact you to talk everything through and provide you with the required information.

Are you ready to receive your tailored estimation on how your digital future could look like?

Are you leveraging AI in your manufacturing company?

Manufacturing processes often generate large volumes of data, which when using Artificial Intelligence (AI) to gain insights and trends in these data, can lead to significant optimizations. This is just one example of how you can leverage AI in your manufacturing company.

Not within project-based manufacturing? Explore the different paths within manufacturing

The way you do business, have a huge impact on the challenges you face. Manufacturing isn't just manufacturing. So if you don't recognize yourself in the challenges above, you are just on a different path.